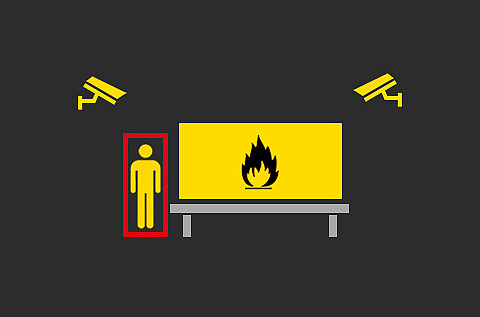

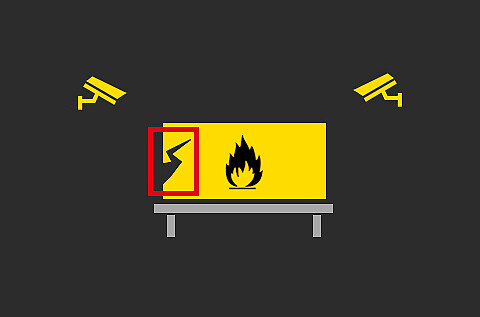

Reduce risk by detecting faults at an early stage

When handling hazardous goods, the early detection of faults can save lives. The combination of video analysis and an interface link to fault detection sensors (gas, temperature etc.) immediately shows staff what is going on at the location.

Your benefit

- Faster reaction through rapid locating of causes and clarification of incidents

- Prevent escalation of major accidents by initiating precautionary action at an early stage

- Pre-evaluation of the situation to protect employees

- Environmental protection through prompt intervention in the event of incidents

This might also interest you

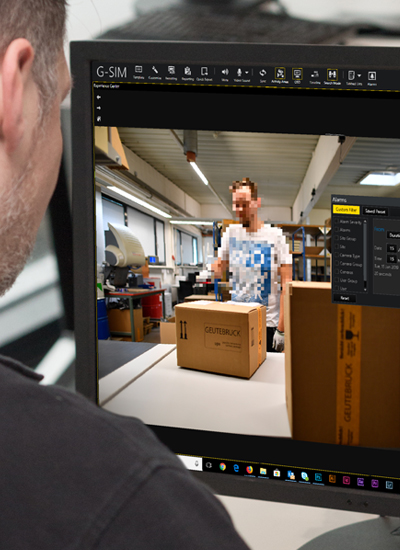

Prevent loss of items

The interface to the ERP system enables you to seach on the order number of a dispatch order. You can view the journey of each package in an order in almost real-time. Incorrectly loaded items can be identified and corrected rapidly.

Document transfers of liability

Transfers of liability can be a source of challenges in the supply chain. At these points, one logistics services provider often needs to prove that the goods were handed off to the next party in the chain in an undamaged condition. Video documentation provides the required court-enforceable evidence.

Boost security at entry points with links to X-ray equipment

By linking X-ray data to video images from security cameras, you can easily determine and record which scanned bags belong to which person.