ARTIFICIAL INTELLIGENCE OPTIMIZATION OF WORK SAFETY MANAGEMENT

Our client is a medium-sized, internationally operating automotive supplier. Company Head Office, Development, Production and Sales are based in Germany.

The state-of-the-art products are unique and used in commercial vehicles, building vehicles and passenger cars worldwide.

THE CHALLANGE

For the company, respect and the responsibility to its employees and their well-being are of paramount importance. A Zero-Accident Strategy is to be implemented for this reason.

All safety precautions must be applied in accordance with the regulations to ensure the protection of workers. Carelessness or failure to comply with the legal protection measures shall be made impossible, health damage shall be strictly avoided.

THE REQUIREMENT

In production, storage and shipping, certain areas may only be accessed with a high-visibility vest and protective helmet. Employees frequently fail to wear both, e.g. following a break or a meeting held outside this security area. Signs are either unintentionally overlooked or intentionally ignored.

This leads to occupational accidents, which the client intends to prevent in future.

The requirement:

- Only employees wearing both a safety vest and a helmet have access to the protected area.

- Access will be barred if safety clothing is incomplete.

- Documentation of Accident Prevention Regulations by video images.

Automatic testing of the protective clothing

Reduction of insurance cases

Interface to access control system

THE GEUTEBRÜCK INDIVIDUAL SOLUTION

The artificial intelligence (AI) based solution for the detection of protective clothing significantly improves work safety.

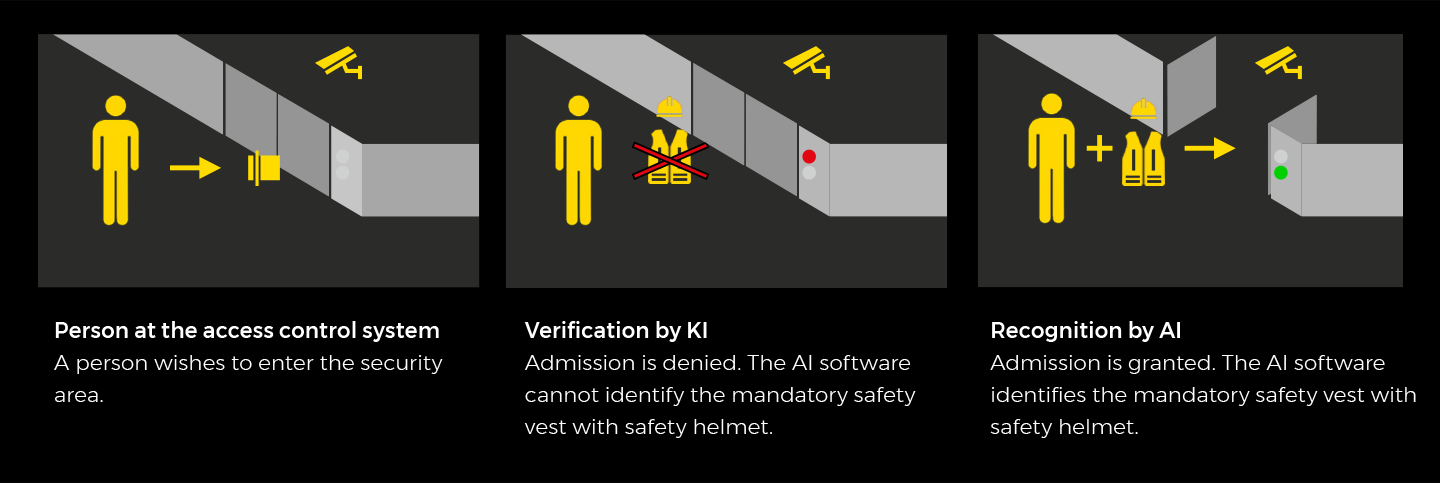

An interface of the Geutebrück system to the automatic door locking system with traffic lights guarantees an

automatic procedure.

When the AI detects the required protective clothing, the safety area door is automatically unlocked. If the AI detects incomplete protective clothing, the entrance remains locked.

THE BENEFITS

- Realistic compliance with a Zero-Accident Strategy

- Avoidance of work-related accidents and resulting health damage

- Sensitization of employees for compliance with safety regulations after breaks or meetings

- Visual documentation as proof of compliance with all legally prescribed protective measures

- Image boost through pioneering role

- Interface to other systems, e.g. time and attendance, is possible

- Protection of privacy rights

IN A NUTSHELL:

- AI-based solution recognizes correctly designed safety clothing

- The employer takes the best possible precautions to ensure safety at work

- Service and Support

- In the Machine Learning Process, our experts „show“ the algorithms as many images of people with/without helmets and with/without warning vests, until the required content is independently identified and processed.

- Depending on individual user rights the faces can be pixelated if the video images have to be retrieved.

- Further objects can be trained, e.g. protective footwear or protective gloves.

- Additional services: patch management, warranty and maintenance.

- Personal: Permanent Geutebrück contact person.