MORE SAFETY IN WASTE DISPOSAL COMPANIES

The client is the operator of a thermal power station respectively a waste incineration plant. It recycles waste from over 620,000 households, municipal facilities and businesses. The thermal processing reduces the volume of waste by 90%. Any residual hazardous substances are filtered out and disposed during the combustion process. Temperatures of up to 1000°C arise during the process, which are used for district heating and electricity generation.

The Challenge

Repeatedly, environmental offenders attempt to dispose of illegal and incorrect substances, which belong in the hazardous waste. This illegal process endangers the employees in the company and can, under some circumstances, escalate into an environmental disaster which then has an impact on an entire region. Up to now, violations have been uncovered first and foremost by employees and rather by coincidence. Polluters can seldom be traced.

The Requirement

- The client intends to take additional visual safety precautions to ensure that illegal disposal is prevented and that polluters can be held accountable. The employees are to be safeguarded from health damage and the environment from the effects of any contamination. To identify the perpetrators, it is essential to have a visual proof that will stand up in court. Cameras will monitor the waste deliveries as well as the dumping process into the oven sluices and the recorded video images will be used to track who discharged which material with which vehicle.

- In an emergency, the cameras will also be used to allow a live view of all areas of the plant, e.g. to inform emergency forces in detail about the situation on site. This saves valuable time and can save life. Because of the heavy dirt in many areas, the cameras have to be extremely resistant, low-maintenance and reliable.

- Additional cameras in special water-cooled housings will document the combustion process.

Vehicle registration linked with video images

Video recordings for judicial use

Interface to existing alarm systems

The Geutebrück Individual Solution

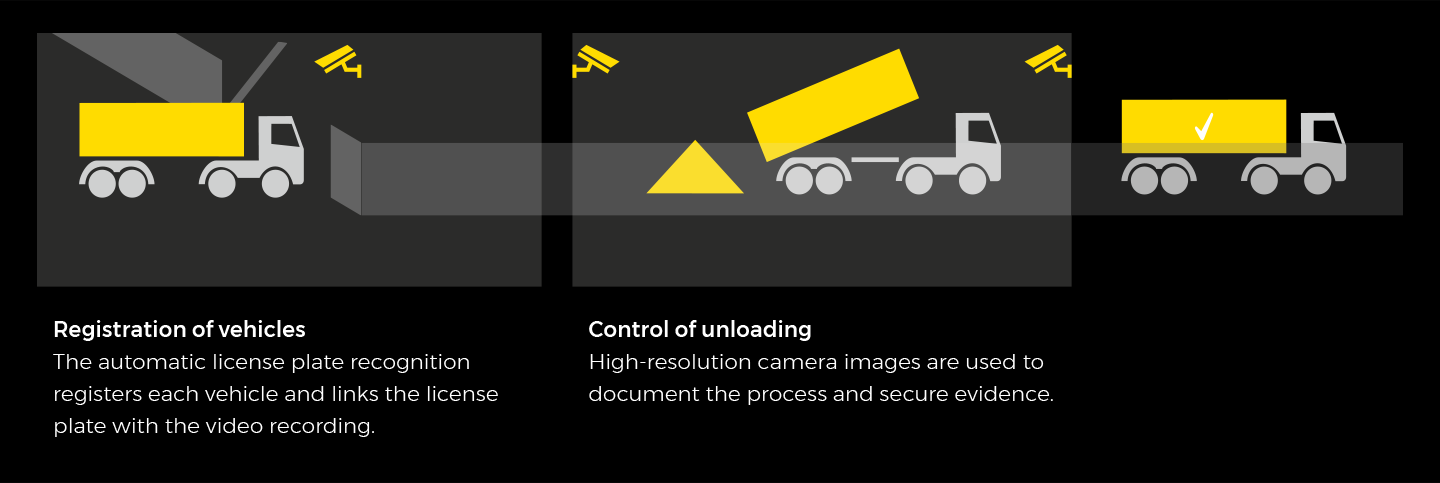

Each vehicle is recorded and registered by automatic number plate recognition (ANPR) on arrival and departure. The location of the vehicles‘ and drivers‘ stay on the site are fully documented with video images. The unloading or dumping of the waste load is recorded with particularly high-resolution cameras (4K) and displayed live. The water-cooled oven cameras also show the combustion process. Thus, it can be detected and confirmed whether hazardous waste e.g. drums with unknown chemicals are dumped into the plant.

The company‘s own intrusion detection and fire alarm system is linked to the Geutebrück solution via interfaces. In hazardous situations, camera images from the affected area are displayed immediately to the personnel both on-site and on mobile devices as an option.

In a crisis, counter-measures can be taken within a few seconds. Extra cameras help to verify the situation. Emergency personnel are provided with images and geographical information in order to optimally prepare for the mission.

THE BENEFITS

Automatic license plate recognition for security, efficiency and control of access routes

Transparency throughout the entire delivery process

Detect hazards at an early stage

Court-proof evidence for the conviction of the perpetrators

More Efficiency and higher Safety on the premises through automated yard management

The fastest reaction possible in the event of a catastrophe through automated alarm management

Highest possible precautions to protect the employers and the environment

IN A NUTSHELL:

- Avoidance of inappropriate waste disposal

- Tight control of all processes

- Highest possible protection against environmental disasters

- Geutebrück Service & Support

- Complete project management including plannig, installation and after-sales service

- Patch management, warranty and maintenance

- Personal: Permanent Geutebrück contact person